|

New challenges arise with such a significant context change Competitiveness is acquired by the summation of the last yearly improvements in product R&D and production processes. This is relevant to physical products, to services and to information systems. It goes without saying that companies with competitiveness improvement rates of 4 percent per annum, for example, will lag far behind those achieving 9 percent per annum. After five years, this difference will be 25 percent, at which stage customers will no longer resist changing supplier –opting for more efficient Thai companies or those from other low cost countries. On top of this, constraints in environment, social requirements, product specifications, equipment sophistication and safety issues will be so time-consuming for the management team that the time remaining will be too short to keep control of the global action plan and solve outstanding complex issues. Employing more management staff as a solution to this will further reduce the organization’s chances of improving competitiveness. In today’s market, companies having only two of the five following strengths are no longer considered “safe” in terms of competitiveness: quality products, quick deliveries, low prices, advanced technology and innovative products. As a benchmark nowadays, three of these five are a must, and within 5 years, all are desired. A 25% improvement requires also awareness of hidden potential and innovative ways of problem solving. HOSHIN : Is how achieving competitive excellence (ACE) by a change management system. See hereafter Hoshin teams as pioneers for higher performances in quality, productivity & lead time.

How much potential is available to achieve the challenge?

Example:

The management of PEUGEOT, after many years of continuous improvement at 7% per year, declared further improvements were no longer possible. Therefore DyAmCo was assigned to introduce Hoshin activities through 5 sessions. Between 18% and 27% improvements were achieved at each HOSHIN session.

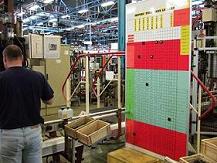

HOSHIN team workshops HOSHIN needs neither a long term plan nor a restructuring of the organization. Rather, it improves on existing available skills, gets people committed to the challenge, make the organization leaner, and set priorities better. HOSHIN brings employees from an exploitation organization into a learning organization. They become able to solve complex issues and implement appropriate solutions. As a result, the time taken between the idea being conceived and the implementation of the improvement can be reduced from 40 weeks to just 40 days. This is the kind of pace that makes market leading companies. The HOSHIN improvement team (Engineers + Technicians + Operators + Supervisor + management) driven by DyAmCo, improves the effectiveness of continuous improvement resources at a rate of 250%. Before performing, conventional skills and work methods are refreshed. Obsolete perceptions are identified and cleared up (5S of Paradigms) in order to implement an efficient teamworking set-up. Everything is taught and applied on the spot. A basic rule: less than 15% of what is taught is not applied within a few days. Conventional training is disconnected from the Gemba (actual job, tasks, specifics), and doubt come up among the trainees when a small detail has to be adapted during the implementation. This amounts to an 85% wastage in training efficiency and is a major cause of missing skills for competitiveness.

Which concepts and skills have to be refreshed and promptly applied ? 1/ Organizational concepts: Just-In-Time, 5S, Kanban, Kaizen, ESCOF, Six Sigma, TPM and quick tool change. 2/ Managements’ way of working: Team work, Mind mapping, Gembutsu investigation, Best people practice. 3/ Deepening involved techniques: Mechanics, Hydraulics, Process, Energy, Cinematic, Material structure, in the context of cross functional teaching. 4/ Effective Management: Balanced +/- management, Speak with data, Coaching activities, PDCA follow up, Audit for sustainability,

Example:

Pragmatic projects

Example: A plant which manufactures engines for BMW was opened 15 months ago.

Nevertheless a TPM activity through a HOSHIN team lead by DyAmCo managed to improve efficiency by 18% within 4 weeks (28 % => 33%). Consequently, they let Hoshin run on three others in order to reach the target and to improve customer deliveries from 8.000 to 13.000 engines per day.

Effectiveness of Team dynamics

A HOSHIN workshop deals simultaneously with many topics such as material flow, information management and process times, quality specifications, customer service, cost effectiveness, and safety and environmental requirements. It’s already tough to keep those seven criteria stable, but to change and improve 3 times faster, one needs more than good will, high skills, a generous budget and clear strategy.

HOSHIN teams care also for the What, Why, Where, When, How, Who and How of making sustainable improvements. DyAmCo guides companies to define optimal boundaries, identify potentials, and fix priorities that match your specifications and corporate strategies.

Example: DARAMIC was challenged by Chinese companies providing good quality filters at lower prices. At first, one Hoshin at the French plant surprised the management by delivering a result that was twice that expected from a [5S + Pull flow] HOSHIN workshop. In addition, a Hoshin Six-Sigma was implemented, reducing wastage due to holes by 60 percent. Later, a SMED reduced scrap during changeover by 3 times. DARAMIC also implemented a HOSHIN in their small German plant (60 staff).

Following this, DARAMIC (Thailand) Co.,Ltd at the 304 Industrial zone, gave DyAmCo an assignment to reduce web folds by 70% through HOSHIN activities. This was such a success that the plant manager secured two other Hoshin activities to solve the Top1 issue “structural deficiencies of the web foil shortening battery life time” and Top2 issue “oil wastage of 1300 litres per day”. The Thai plant subsequently achieved number one status for continuous improvement for the DARAMIC group worldwide.

A/ Savings on the Thai plant out of these 3 Hoshin activities show an ROI shorter than any other project. The Thai plant became the leader for Continuous Improvement for the 5 other countries. B/ Gembutsu investigation is amazing and reliable in addressing complex problems C/ People would like to join the next Hoshin team These employees attained the skills, the soul, and the trust to meet the new challenge of World Wide Performance. They are already on the way. A few companies are also applying HOSIN to develop steps for improved competitiveness. The others will struggle and will have to either downsize their activities or relocate.

For more information please contact:

Glossary : GEMBUTSU : A complex problem still not under control after 2 or 3 conventional action plans GEMBA : The workplaces where the added value is produced KAIZEN : Clever and pragmatic solutions put spontaneously on place by the “idea owner” LEAN MANUFACTURING : TPM , SMED, Pull Flow, PoKaYoke, JIT, U-Cell, One piece flow SIX-SIGMA : Get capability by DMAIC under Black-belt leader. 5S PARADIGMS : Identify, clear and class perceptions, then implement new beliefs.

|

There is evidence that some people achieve only a part of work they are asked for. Also, these tasks were defined by one person, or sometimes were obsolete. Furthermore, the equipment they are using is neither reliable nor suitable for the process, thus reducing its capability to meet quality specifications. On top of this, neither product specification nor the content of “non-value-added” requirements are clear enough. In a typical company, for example, staff might do 80 percent of what is asked of them, the tasks of which are 70 percent relevant. The equipment makes 85% up time, and the product contains 70% added value functionalities. So, global effectiveness is 0,80x0,70x0,85x0,70 = 33%. The 67% remaining constitutes the potential to reach World Class best practices. In administrative offices and institutions, where problems do not physically pile up, effectiveness may be even less than 25 percent. Managers may know this, but how to they make the breakthrough?

There is evidence that some people achieve only a part of work they are asked for. Also, these tasks were defined by one person, or sometimes were obsolete. Furthermore, the equipment they are using is neither reliable nor suitable for the process, thus reducing its capability to meet quality specifications. On top of this, neither product specification nor the content of “non-value-added” requirements are clear enough. In a typical company, for example, staff might do 80 percent of what is asked of them, the tasks of which are 70 percent relevant. The equipment makes 85% up time, and the product contains 70% added value functionalities. So, global effectiveness is 0,80x0,70x0,85x0,70 = 33%. The 67% remaining constitutes the potential to reach World Class best practices. In administrative offices and institutions, where problems do not physically pile up, effectiveness may be even less than 25 percent. Managers may know this, but how to they make the breakthrough?

A pragmatic project, promptly implemented and at a competitive cost is the major outcome of a Kaizen spirit. This is a high potential alternative to sophisticated techniques, heavy investment and investment cartoons at low return on investment (ROI). In a Hoshin project, teams practice a Kaizen spirit. They respect the ESCOF chronology and check if the ROI is below 5 months. The project contains 40 to 90 Kaizen activities and 4 to 9 fundamental process improvements. These are defined, implemented and controlled according to the PDCA concept and frame. The Hoshin leader is required to practice hands-on activities as well as the team, so as to initiate and motivate them.

A pragmatic project, promptly implemented and at a competitive cost is the major outcome of a Kaizen spirit. This is a high potential alternative to sophisticated techniques, heavy investment and investment cartoons at low return on investment (ROI). In a Hoshin project, teams practice a Kaizen spirit. They respect the ESCOF chronology and check if the ROI is below 5 months. The project contains 40 to 90 Kaizen activities and 4 to 9 fundamental process improvements. These are defined, implemented and controlled according to the PDCA concept and frame. The Hoshin leader is required to practice hands-on activities as well as the team, so as to initiate and motivate them.

A team dynamic is the most effective way to help a group carry out a project. For understanding why, take the example of one engineer and two technicians left to solve three problems on their own. After they have elaborated their action plan, while implementing they will try to adapt or even abandon their outcome. If they are very good friends, they will only have to scratch 30%, if not, there may be 70% waste. But, if you let them work together to design the solution it will be [3 individual brain] + [3 pioneer brain]. As result, the content will be 450 (3x100+3x50) instead of 180 (300-40%), therefore resulting in 250% effectiveness. Schools teach individuals and managers struggle through long lasting meetings in 5 or 20 steps. Each time, 30% of the time is wasted on refreshing memories and re-establishing trust. Many details, while going into detail to solve problems, will at the same time challenge the multidisciplinary skills of the Hoshin’s leadership, techniques, problem solving, process and Lean manufacturing concepts. Awareness: The Hoshin leader is not in charge to solve, but to guide and to get it solved. His job consists of continued questioning, identifying if a solution addresses the root cause of the problem, time keeping, and ROI containment. DyAmCo (Thailand) Co., Ltd is teaching these abilities.

A team dynamic is the most effective way to help a group carry out a project. For understanding why, take the example of one engineer and two technicians left to solve three problems on their own. After they have elaborated their action plan, while implementing they will try to adapt or even abandon their outcome. If they are very good friends, they will only have to scratch 30%, if not, there may be 70% waste. But, if you let them work together to design the solution it will be [3 individual brain] + [3 pioneer brain]. As result, the content will be 450 (3x100+3x50) instead of 180 (300-40%), therefore resulting in 250% effectiveness. Schools teach individuals and managers struggle through long lasting meetings in 5 or 20 steps. Each time, 30% of the time is wasted on refreshing memories and re-establishing trust. Many details, while going into detail to solve problems, will at the same time challenge the multidisciplinary skills of the Hoshin’s leadership, techniques, problem solving, process and Lean manufacturing concepts. Awareness: The Hoshin leader is not in charge to solve, but to guide and to get it solved. His job consists of continued questioning, identifying if a solution addresses the root cause of the problem, time keeping, and ROI containment. DyAmCo (Thailand) Co., Ltd is teaching these abilities.